Description

BRIEF INTRODUCTION

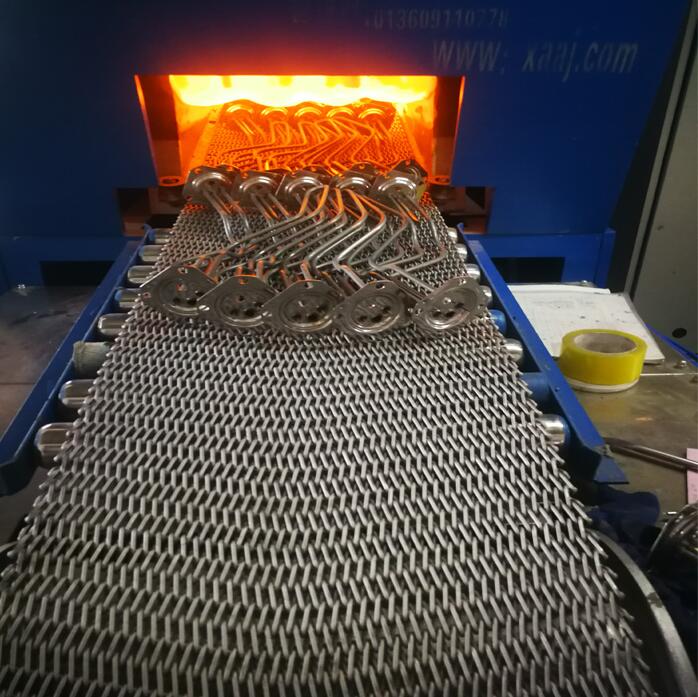

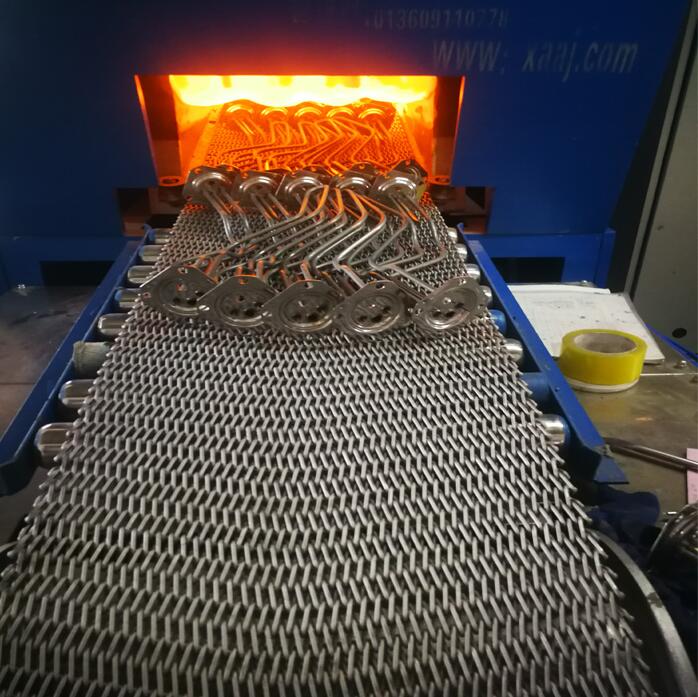

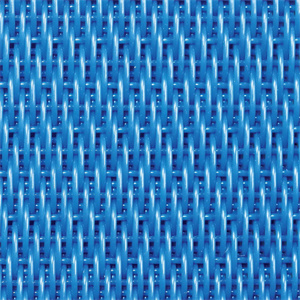

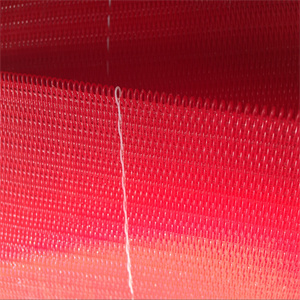

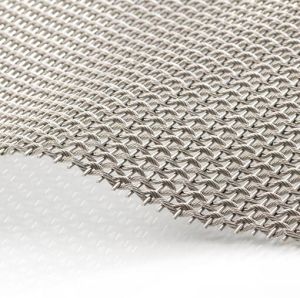

Brazing furnace conveyor belts are widely used in the continuous operation of brazing production lines. Mesh belts adopt different weaving methods according to different brazed parts. They have high tensile strength and are not easily deformed. They are widely used in automobiles, diesel engines, aerospace, air conditioning and refrigeration, electric heating pipes, gas water heaters, electronics, microwave magnetrons, and other industries. Brazing and heat treatment of stainless steel, carbon steel, aluminum, brass, copper, ceramic, and other parts. It can be applied to the working temperature of about 750 degrees to 1200 degrees Celsius. It is generally made of 316L material or AISI314 material. Our engineers can provide different design solutions according to specific working conditions.

Advantage:

1. Maximum working temperature 1200℃

2. The structure is stable and not prone to snaking

3. High tensile strength and large load capacity

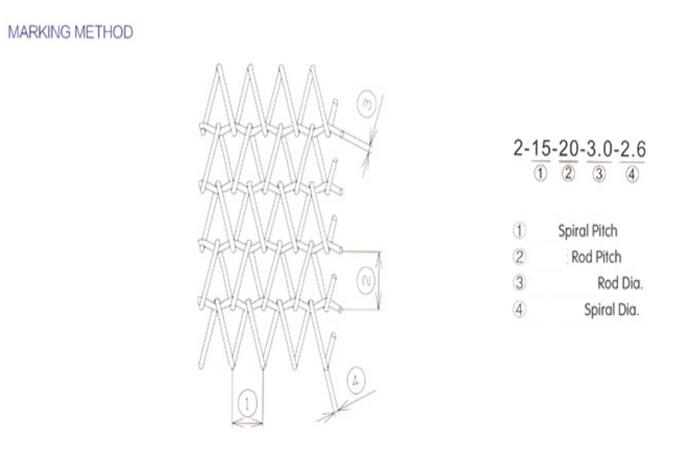

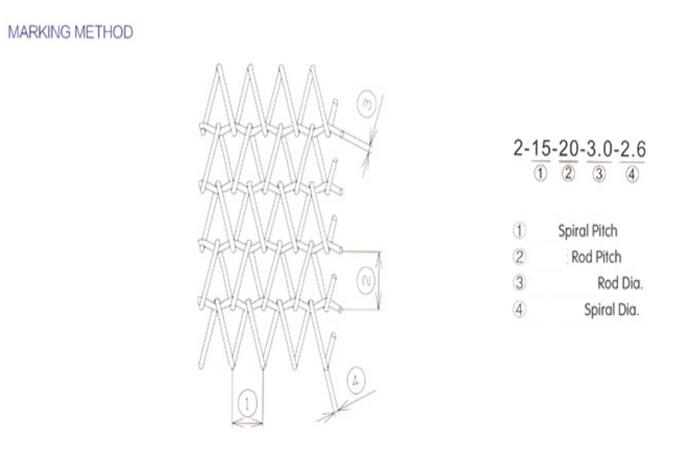

Marking Method:

General specifications:

Y2-10-15-2.6-2.6

Y2-15- -20-2.6-2.3

Y2-10-15-2.6-2.3

Y2-8-12-2.3-2.3

Y2-12-18-2.3-2.0

Y2-8-12-2.3-2.0

Y2-6-9-2.0-2.0

Y2-10-15-2.0-1.8

Y2-6-9-1.8-1.8.

Y2-10-15-1.8-1.6

Y2-7-10-1.8-1.6

Y2-5-7-1.6-1.6

Other specifications support customization

Optional materials: SUS304, SUS316, SUS310, SUS314 ETC

Click directly to send a message via WhatsApp

Click directly to send a message via WhatsApp

Click directly to send a message via WhatsApp

Click directly to send a message via WhatsApp

)

)